IMPLEMENT: WINERY ENERGY EFFICIENCY & RENEWABLES

Energy Use in Wineries

The primary source of greenhouse gas emissions from winery operations stems from using electricity, diesel, and other fossil fuels to power facilities, machinery and vehicles. The main energy uses in a winery include refrigeration, lighting, pumps/motors, air compressors, water treatment, filtration, heating, vehicles and HVAC for occupied spaces. By reducing fuel and electricity usage in these systems and equipment, a winery can reduce its carbon footprint and help mitigate climate change. Reducing energy consumption also reduces energy costs which benefits the bottom line while conserving natural resources.

Priority Practices Quick Links:

-

Power with Renewable Energy

The Goal of Decarbonization

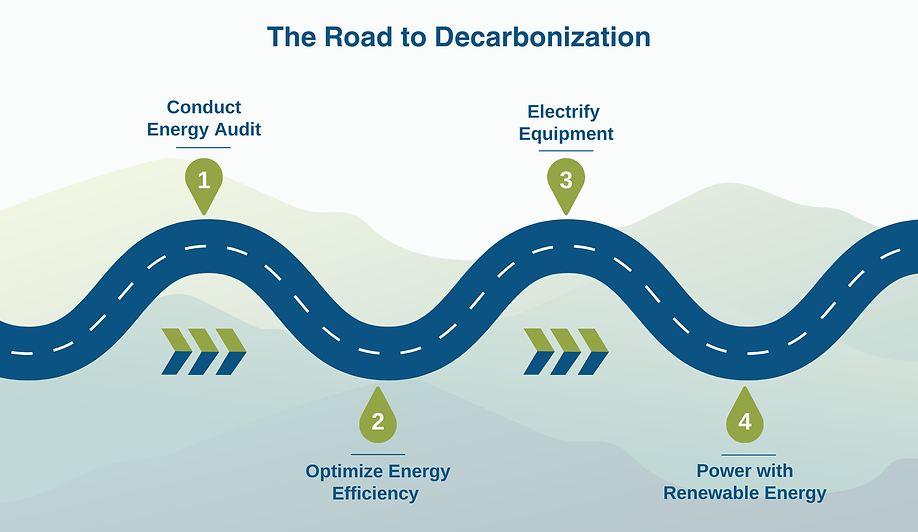

One of the main objectives of climate action is decarbonization (using carbon-free renewable energy sources for all energy needs). To achieve decarbonization, first overall energy use must be reduced and optimized, then wherever possible equipment should be powered with electricity and finally, the sources of electricity should come from renewable energy such as solar and wind. Technology advances are still needed to efficiently electrify all winery equipment, such as hot water systems which are typically powered by fuel, however, there are many steps outlined below that can move your winery operation closer to decarbonization.

.png)

1. Conduct an Energy Audit

Before installing a renewable energy system or implementing energy efficiency measures, an energy audit should be conducted. The intent of an energy audit is to assess energy-consuming processes and equipment to compile a list of potential changes in behavior or technology that can reduce overall energy consumption. This can result in immediate cost savings for any winery and provide more insight into production operations. Once energy consumption is minimized, then renewable energy options can be explored that will meet the winery’s energy needs, which can prevent added costs from installing renewable energy systems that provide more energy than needed.

Use the following resource to assess your energy related practices, conduct an equipment inventory, prioritize potential efficiency opportunities and develop an energy management plan.

-

DIY Winery Energy Audit Tool: This do-it-yourself tool can be used internally by winery staff to assess energy-consuming processes and equipment and identify improvement opportunities. The tool is provided as an Excel document (which allows for automatic calculations and customized energy use charts) or a Word document and is accompanied by a tutorial video.

2. Optimize Energy Efficiency

Once you have completed an energy audit, you can prioritize potential opportunities for efficiency. Since refrigeration is one of the largest sources of energy use in a vineyard, looking for opportunities to improve efficiency of your refrigeration system is a great place to start.

The following list covers the main areas of energy used in a winery and are covered in detail in the DIY Winery Energy Audit Tool. Add relevant practices to your Climate Action Plan Worksheet to help track practices and create timelines for implementation, such as when equipment is due for an upgrade or maintenance. You can also run the CSWA Climate Smart Report to easily identify which energy efficiency practices are already implemented and where there are improvement opportunities.

-

Refrigeration: Accounts for approximately 30% of electric energy use for an average winery.

-

Buildings and Tanks: While neither the building or tanks use energy directly, their design and operation directly impacts the performance of mechanical systems.

-

Lighting: Optimizing winery lighting reduces energy use, improves productivity and increases worker safety.

-

Boilers and Hot Water: Hot water is often responsible for much of a winery’s gas usage.

-

Air Compressors: Provide air used for specialized pumps and running bottling equipment.

-

Pumps/Motors: High efficiency motors, variable frequency drives and automated controls can all be used to only pump and move the equipment/liquid volume needed.

-

Water Treatment: Treating process water is an important part of operating a winery for any location not connected to a city source and can account for a significant portion of total site electricity use.

-

HVAC: Heating Ventilation & Air Conditioning (HVAC) refers to energy used to control the air temperature of indoor spaces such as office space, barrel rooms, bottling lines, tasting rooms, case good warehouses, etc.

-

Vehicles: Both onsite (forklifts, trucks, ATVs, etc.) and off-site vehicles (trucks, sales fleet, etc.) that are directly owned or operated by the winery.

-

Filtration: Winery filtration equipment varies based on the winery but can have a noticeable impact on facility energy use.

3. Electrify Equipment

As noted above, a large source of a winery’s carbon footprint is from the combustion of fossil fuels to operate winery equipment and systems. To decarbonize equipment, the equipment needs to be powered with electricity that can be sourced from renewable energy. As of June 2024, zero-emission electric forklifts are included in a California regulation designed to phase-out fuel powered forklifts to help California meet its climate goals through zero-emission technology.

4. Power with Renewable Energy

Many wineries install solar panels as part of their renewable energy strategies, with a growing number adding batteries for storage. Installing solar photovoltaic panels can be a great investment, especially as electricity costs continually increase. As of February 2025, the Federal Government offers a Tax Credit of up to 30% for zero-emissions energy projects. There are more options for incorporating renewable energy into your operations than rooftop solar panels. You can also explore floating solar panels on irrigation ponds and above parking lots, which has an added benefit of providing shade.

-

Winery Energy Efficiency & Renewables - Implementation Guide: The guide outlines key practices and resources to support implementation of an energy audit, energy efficiency measures for winery equipment and lighting, and renewable energy, along with cost-share, rebate and incentive opportunities to help finance energy efficiency upgrades and renewable energy.